Researchers from the Massachusetts Institute of Technology (MIT) have developed a new 3D printing technique that enables users to alter the color of 3D-printed objects made out of photochromic ink by exposing them to ultraviolet (UV) light.

The group from MIT's Computer Science and Artificial Intelligence Laboratory has designed a customizable, photochromic ink that can serve as 3D printing material. The proprietary ink is composed of a base dye, various light-adaptable dyes, and a photoinitiator, which hardens the base dye during 3D printing.

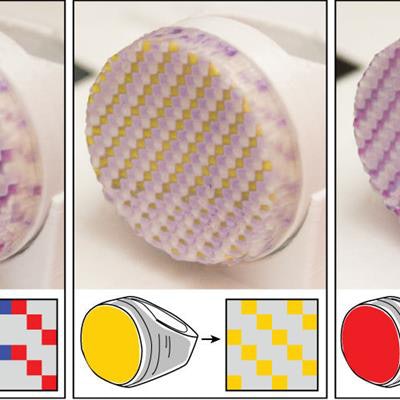

Referred to as ColorFab, the group's 3D printing workflow uses this ink to create 3D-printed objects following a series of steps:

- Upload appropriate images of an object into the ColorFab interface.

- Select the desired color patterns for the object.

- 3D print the object.

- Place the object on a platform and alter colors via the interface.

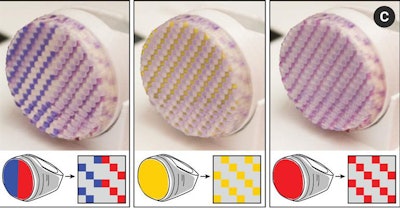

During the printing process, the interface automatically unites photochromic ink of different colors in a dense, pixelated pattern based on the design of the object. Exposing the finished 3D-printed object to UV light changes the color of the object according to the color pattern designated on the interface prior to 3D printing.

The ColorFab interface can create 3D-printed models of different colors, with areas that activate upon exposure to UV light. Image courtesy of MIT's Computer Science and Artificial Intelligence Laboratory.

The ColorFab interface can create 3D-printed models of different colors, with areas that activate upon exposure to UV light. Image courtesy of MIT's Computer Science and Artificial Intelligence Laboratory.Fully recoloring an object with this technique currently takes 23 minutes, but MIT professor Stefanie Mueller and colleagues plan to speed up the process by installing a more powerful light source or adding more light-adaptable dye to the ink. They also hope to improve the grainy quality of the coloring by activating colors closer together.